All Alternative Lifting/Jacking Systems Articles

The systems have a lifting capacity of 800 tonnes per tower

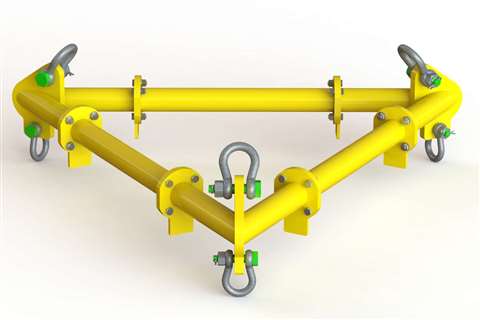

The new product from UK lifting engineering specialist Modulift is designed for three point lifts and circular lifts

Dal-Lago, part of DLC Consulting, will distribute Verton’s lifting and orientation technology

The partnership will help sell the Lifting Equipment Store (LES) product range to large companies, including Botswana mines

Cost effective hydraulic gantries prove their versatility for various projects

Confined space in factories, industrial plants and hospitals are all natural environments for the new Enerpac telescopic gantry

With UK infrastructure output rising, rental firm’s new high-capacity cylinders will target bridge sector

Gantry systems extend the realm of industrial lifting heavier and higher.

Erection of a refinery vessel weighing almost 4,000 tonnes set a new record on a Chinese refinery project

Mammoet South Africa used jacks and SPMT to move a 600 tonne ship to a dock in South Africa

Innovativ Hoisting uses Böcker AHK 36 trailer crane to lift one of the largest stained glass windows in the USA

Engineered Rigging uses Enerpac strand jacks as effective crane alternative in Cline Avenue Bridge build

RMMV to have up to 4,000 Hiab hooklifts by 2027, plus 110 units to go to the Swiss Army

Our annual TopLift competition gives you the opportunity to vote on your favourite lift from our selection of ten impressive lifts featured in the magazine over the last year.

Laso uses Enerpac gantry and side shift to lift and place 160 tonne automotive presses

Barnhart Crane and Rigging in the USA has announced its acquisition of Days Machinery Movers, including all personnel and equipment

Minimal disruption and improved safety are claimed benefits of new solution for the removal of concrete bridges over railway lines

SPMT, girder deck and unique mobile lifting system used as alternative to a mobile crane for German bridge replacement

Installation of a huge combination tower at a refinery in Beaumont, TX required expert planning and execution by the team at Deep South Crane & Rigging

New CS350 climbing jack lifting system joins CS1000 and CS5000 models in the Sarens heavy lift fleet

partnercontentplaceholder

blockintro

partnercontentplaceholder

blockintro

partnercontentplaceholder

blockintro

partnercontentplaceholder

blockintro