A guide to demystifying pressure profiles

08 November 2022

Stay safe by understanding how pressures imposed by crawler crane tracks vary in use and depend on many factors.

When lifting with a mobile crane, it is vital to provide a level load-sustaining base to support the crane and avoid it tipping in use.

Figure 1 A 220-ton class crawler crane in main boom configuration

Figure 1 A 220-ton class crawler crane in main boom configuration

Generally, this is well understood and is taken seriously. However, cranes can also impose high loads and pressures in other circumstances such as when raising a boom and jib or, in the case of a crawler crane, when relocating unloaded. This is less well-understood and has high potential for creating problems.

First, some fundamentals. Achieving good support may involve some ground preparation and/or improvement and likely some matting to distribute the imposed loads to a level that the ground can safely withstand without failure or excessive settlement.

When designing a support system, there are some logical steps to be taken and questions to be asked:

- What is the maximum load or pressure the crane will impose in use?

- What can the ground safely withstand?

- How effective is the matting in distributing the loads?

To address these questions, there are tools available.

Figure 2: Minimum radius over the front

Figure 2: Minimum radius over the front

Many crane manufacturers (and others) offer ground bearing pressure estimators or software (stand-alone or in-built) that allow the lift planner to estimate the loads and pressures the crane will impose.

Regarding ground capability, there are a number of avenues to determining a design pressure, including soil testing, boring logs, historical information, codes and presumptive figures.

For matting analysis there is advice to be found in text books and publications. If all else fails, there are conservative rules of thumb (not recommended).

Conservative approach

There are relatively few instances of cranes overturning during lifting when these questions are correctly addressed.

Figure 3 Minimum radius over the corner

Figure 3 Minimum radius over the corner

In the real world, however, when dealing with non-engineered more “routine” operations and less certain ground conditions without a defined bearing figure and no geotechnical support, it might be appropriate to simply take a very conservative approach to load distribution to cover the uncertainty.

So, if we are doing our job right, when planning and executing a lifting operation, we should be giving some concentrated attention to ensuring the crane is well supported. This is all well and good when actually lifting, but what about the loads and pressures that are imposed when raising a long boom or relocating a crawler crane?

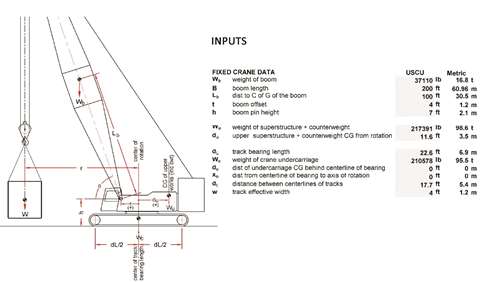

To investigate this, a generic ground bearing pressure estimator has been used. I have chosen to populate it with representative data for a 220-ton (200 metric ton) class crawler crane in the main boom configuration with 200 feet (60.1 meters) of boom and maximum machine and auxiliary counterweight.

Figure 4: Mid chart over the front

Figure 4: Mid chart over the front

Typical workhorse

There is no particular reason for choosing this machine except that I have good data, and the machine is typical of the workhorses on many construction sites. While the estimator yields believable results, the object is not to be absolute with the track bearing pressures. After all, this crane and configuration are arbitrary. But it illustrates relative magnitudes of pressures when the crane is used in different ways. The principles this investigation reveals should be generally applicable, even to heavier cranes imposing higher pressures, and should hopefully guide behavior.

Figure 5 Maximum radius over the front

Figure 5 Maximum radius over the front

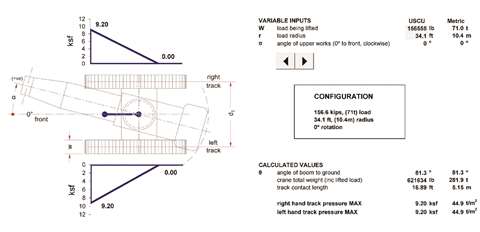

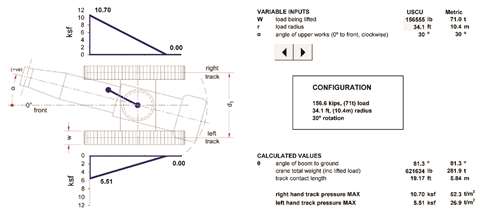

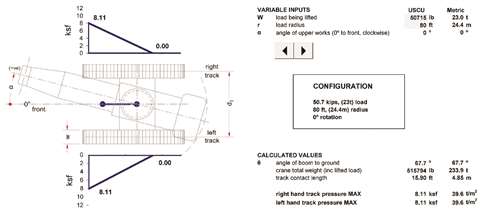

Several instances are modelled. In all cases (with one noted exception) the maximum operating track pressures are calculated on the basis of lifting at chart capacity for the radius in question. The full track width is assumed for bearing. The blue “dumbbell” in the graphic represents the orientation of the upper works.

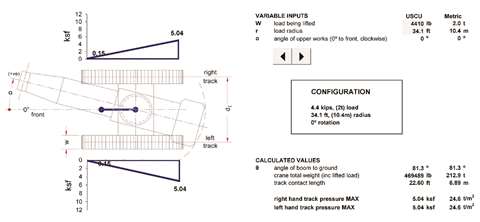

Minimum radius – over the front. First, for comparative purposes, the pressure when lifting 156.5 kips over the front (0 0) at the minimum radius of 34.1 feet. The peak track pressures are about 9.16 ksf at the front. The distribution is triangular and only about 17 feet of the track length is loaded (about 80 percent).

Minimum radius over the corner. If the upper works are then slewed (swung), the worst instance is with the upperworks over the corner at about 30 degrees. The peak track pressure on the right track increases to about 10.7 ksf.

Figure 6 Maximum radius over the side

Figure 6 Maximum radius over the side

Mid chart – over the front. At mid-chart, say 80 foot radius, over the front, the maximum load is 50.7 kips and the pressure is about 8.1 ksf, which is marginally less than the minimum radius situation. The distribution is still triangular and about 70 percent (15.9 feet) of the track length is loaded.

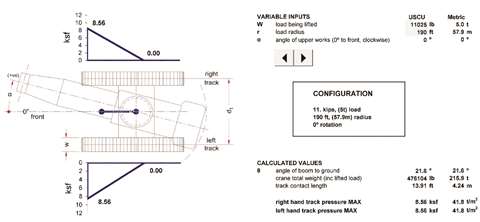

Maximum radius – over the front. At the maximum radius of 190 feet, the crane can lift 11 kips. The peak track pressure over the front is about 8.56 ksf, which is similar to the previous examples; about 13.9 feet (60 percent) of the track length is loaded.

Figure 7 Raising unloaded boom

Figure 7 Raising unloaded boom

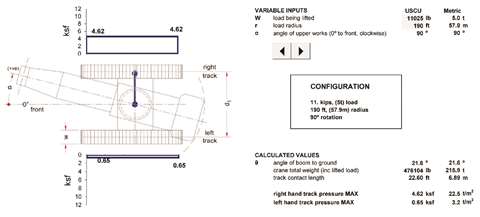

Maximum radius – over the side. If you were to lift that same load, at the same radius, over the side, the entire bearing length of the track would be evenly loaded and the most highly loaded track would see about 4.6 ksf. (The other track only sees a pressure of about 0.65 ksf. There is, therefore, a reduction in peak pressure of about 50 percent; so, the orientation of the tracks is worth considering when looking to minimize peak pressures and thereby ground preparation.

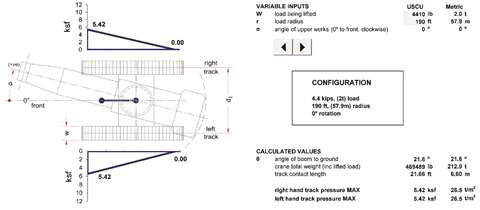

Raising unloaded boom. When raising the boom unloaded (I applied 2.2 tons for a hook block) over the front, the maximum pressure is about 5.4 ksf.

It should be noted that this crane can self-raise a much longer boom than 200 feet and the pressure would be a lot higher.

Figure 8 Perfect balance

Figure 8 Perfect balance

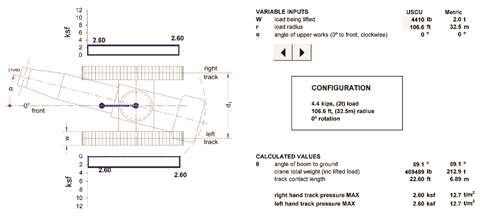

Perfect balance. As the boom is further raised, still with 2 tons suspended, there is a point at which the crane is perfectly balanced, both tracks being evenly loaded at about 2.6 ksf.

This would be an optimum (from a pressure perspective) for crawling the crane to relocate it, being only about a third of typical peak pressures when lifting. It is quite likely that a decent site road could cope with this magnitude of undistributed pressure (although that should be verified). Note that in this state of balance, swinging the crane does not change to pressure distribution.

Figure 9 Crane back-heavy

Figure 9 Crane back-heavy

Crane back-heavy. If the crane is boomed back to minimum radius with the boom over the front, in this instance the whole length of the track is engaged, but the crane is back-heavy and the peak pressures are about 5 ksf. This might not be acceptable on a site road, so again you would need to verify this.

This article was first published in International Cranes and Specialized Transport magazine in June 2020.

- Use the tools to best inform yourself when planning a lift.

- Rules of thumb for estimating loads and mat sizing are a poor substitute for good information and should only be used with caution and be very conservative.

- The peak track pressure in our example was similar across the operating range when lifting at maximum chart capacity.

Whether lifting or relocating a crane, be sure to consider and cater accordingly.

- Less (length) of the track is loaded as radius increases when lifting at chart capacity.

- If the lifting operation can be arranged such that the boom is directly over the side when at long radius, the pressure will be evenly distributed along the tracks, and the most highly loaded track will be at only half the peak pressure had we been over the front.

- When raising a crane boom the pressures can initially be very high and, if a crawler crane, it might be better to raise the boom over the side to better spread the load and reduce the pressure.

- When relocating a crawler crane, there will be an optimum mid-range radius at which the crane is well balanced and pressures are minimized, in our example only about one-third of typical lifting peak pressures. It is recommended that this radius is identified and used to minimize required ground preparation.

- If the unloaded crawler crane is boomed back to minimum radius during relocation, the crane would be very back heavy. In our example, the peak (backwards) track pressure would be about half the typical maximum peak pressure when lifting at chart capacity. Cranes and configurations may differ but the principle remains.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.