All-electric Liebherr modernises port

15 June 2023

Norwegian port Borg Havn is investing in a new all-electric harbour crane. The Liebherr LPS 420 E portal slewing crane will be the first of its kind delivered in Norway.

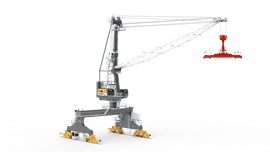

The crane fits into the electrified infrastructure of the port, and is able to perform its work locally emission free (Image: Liebherr)

The crane fits into the electrified infrastructure of the port, and is able to perform its work locally emission free (Image: Liebherr)

All crane movements like luffing, hoisting, slewing and travelling are done by electric motors.

The LPS 420 E can be supplied with high or low voltage, depending on the transformer requirements.

This ensures that Borg Havn can fulfil its logistical operations while reducing its environmental footprint.

Borg Havn is a multi-purpose port which handles all types of cargo like containers, bulk, general cargo, and heavy lift. It’s the third biggest container port in Norway, with 67,249 TEUs in 2021, which is an increase of 14 per cent from 2020.

The LPS 420 E will be used for all types of operation and is the first Liebherr crane at the port.

The contract for the new crane was entered into in March 2022.

Renewing fleets

“This is a large investment for Borg Havn,” said Port director Tore Lundestad. “Renewing and modernising our crane fleet in line with harbour activity is crucial to us. Among the main reasons for our investment in the LPS 420 E is its more environmentally friendly profile, which allows us to greatly reduce emissions and noise in the area.”

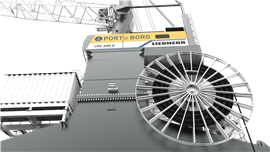

The all-electric LPS 420 E is fully able to operate without the need for hydraulic oil or a diesel engine. (Image: Liebherr)

The all-electric LPS 420 E is fully able to operate without the need for hydraulic oil or a diesel engine. (Image: Liebherr)

It is estimated that as much as 7 % of greenhouse gas emissions from shipping occur while the vessels are completely stationary in the harbour. Life on board also needs electricity when the vessel is docked.

The ships therefore have the auxiliary engines running to keep the systems running.

The investment in shore power is an important measure to cut. Borg Havn produces its own energy from solar cells which are connected to an internal grid. The maximum output is 2 MW, which on sunny days powers all five cranes in the port with their own power in addition to shore power.

Based on the modernized electric infrastructure of the port, the LPS 420 E is equipped to provide optimal and safe operations.

With the Liebherr active-front-end frequency converter, deviations in the voltage supply can be compensated easily for safe and stable operation. To accommodate potentially limited space and any harsh environmental conditions, a liquid-cooled performance capacitor system was implemented.

This Liebherr-built component, known as LiCaTronic, has proven itself in Liebherr ship-to-shore gantry cranes and material handlers.

Handling capabilities

A turnover of up to 1,200 tonnes per hour allows the crane to exceed the average turnover of comparable all-electric cranes in the market. With up to 30 cycles per hour, the LPS 420 E is an ideal solution when it comes to container handling performance.

An observer cabin attached near the tracks at the bottom of the crane adds another layer of supervision for additional workers to keep an eye on the crane’s operations. (Image: Liebherr)

An observer cabin attached near the tracks at the bottom of the crane adds another layer of supervision for additional workers to keep an eye on the crane’s operations. (Image: Liebherr)

The crane can be fitted with various types of fixed or telescopic spreaders on a 60 tonne load chart for twin-lift container operation.

A maximum outreach of up to 48 metres allows for ships up to Panamax class size to be served. This makes the crane the ideal electrical driven solution for bulk handling.

The main components of the E-drive are liquid cooled and the heat is dissipated by heat exchangers.

The fully closed liquid cooling system in combination with the heat exchanger are installed on top of the slewing platform. According to this, no overpressure unit is necessary to prevent dust coming inside the machinery house, which is a big benefit for cranes working in a dusty environment.

The crane is expected to be delivered in late 2023.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.