Emerging trends and new models in the gantry market

03 May 2022

ACT rounds up the latest products and innovative gantry features hitting North America.

With the the passage last fall of the Infrastructure Investment and Jobs Act and the imminent recovery of the construction industry, gantry manufacturers are optimistic and seeing improvements across the board.

“The long slowdown caused by the pandemic was challenging to most in our industry, but I think we are all coming out of it stronger,” said Kevin Johnston, president, J&R Engineering. “In 2022, we have seen an upturn in our gantry orders as our clients are retiring older systems, upgrading their fleets and more companies are expanding their operations to include hydraulic gantries in their inventory.”

J&R Engineering responded to market demand with their Lift-N-Lock Hydraulic Boom gantry series.

J&R Engineering responded to market demand with their Lift-N-Lock Hydraulic Boom gantry series.

These unique specialized lifting machines are often tasked with the jobs that cranes can’t handle. Mobile, innovative and versatile, gantries are an MVP machine that can be used in a variety of industries and in locations that other heavy lifting equipment cannot access.

Emerging trends

Companies are also utilizing hydraulic gantries to lift higher and heavier loads. Specifically, J&R Engineering has responded to the recovering market demand with their Lift-N-Lock Hydraulic Boom gantry series with models that can reach 50-foot heights and four housing system capacities for up to 1,300 tons.

“Our Bolt-on Boom extensions, that raise the lift beam height from the top of the gantry, are also becoming quite popular,” Johnston said. “They are available on most of our gantries currently in the field and on all new Lift-N-Lock models.”

Another notable trend that Johnston pointed out is that the hydraulic gantry has become a standard tool for various heavy lift projects because of their compact size, versatility and ease of use.

“As such, the focus of the industry needs to be on proper operator and project engineering training,” Johnston emphasized. “A lot of gantry lifting projects look similar, but a thorough understanding of ground loading, strength of materials and unique operating procedures of different types of gantries are required to operate and plan these projects safely and successfully.”

Peter Crisci, product line director, Enerpac, echoed this sentiment.

The Enerpac ML40 Mini Gantry is an ideal solution for performing plant relocations, machinery installations, machinery maintenance and specialized rigging projects.

The Enerpac ML40 Mini Gantry is an ideal solution for performing plant relocations, machinery installations, machinery maintenance and specialized rigging projects.

“Skilled labor is aging out of the industry, facilitating the need for smarter machines making gantry jobs easier and safer to set-up and operate,” he said. “Schedules and space to perform work is getting tighter, facilitating the need for more compact smart equipment to perform heavy lifting jobs.”

Capitalizing on this improving industry, ACT reached out to gantry OEMs across North America for information about their latest and greatest gantry products.

Lift Systems

While maintaining standard product lines in both the hydraulic gantry and mobile pick and carry segments, Lift Systems has been actively broadening their base with custom design build projects. Due to the sensitive nature of the equipment applications, and non-disclosure agreements, Lift Systems is precluded from publicly divulging specific project details. However, some general highlights of these endeavors that are translatable to the hydraulic gantry product lines can be shared.

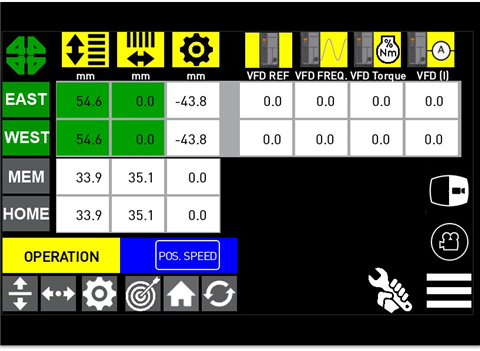

CARL touchscreens support intuitive operator navigation features and video display for remote operator presence, positional feedback and multi-screen linkage.

CARL touchscreens support intuitive operator navigation features and video display for remote operator presence, positional feedback and multi-screen linkage.

The CARL (Computer Assisted Remote Lifting) platform is once again proving its adaptability in these custom build scenarios. Lift Systems has been able to add even more accuracy and precision to the CARL platform through new innovations in open-source sensor technology. In hydraulic gantry applications, 25-millimeter hysteresis is the still the standard supply, with 10- millimeter hysteresis among four jacks available as an option, with 6-millimeter achievable with reduced operational speeds. On purely mechanical gantry applications a 1-millimeter hysteresis is the norm with four jack applications. Other programmable features include electronic interlocks to prevent unintended motions, unparalleled sensor feedback and position memory recalls for applications that require repetitive motions within a tight tolerance. CARL touchscreens support intuitive operator navigation features and video display for remote operator presence, positional feedback and multi-screen linkage for expanded capabilities.

On the service side of CARL, the standard supplied Bluetooth module allows for remote programming and diagnostics in the field. This feature has proved invaluable since the start of the COVID-19 pandemic, when initial travel restrictions hampered in-person support, but more importantly, it has helped keep costs lower in the current inflationary environment by eliminating travel costs whenever possible. Another benefit of less travel time allows for further optimization of valuable skilled human capital resources in tight labor market.

Enerpac

The Enerpac SL-series and SBL-series gantries have long been trusted by lifting professionals. The company provides a safe and efficient way to lift and position heavy loads in applications where traditional cranes will not fit and permanent overhead cranes are not an option. When used with a track system, Enerpac hydraulic gantries also provide a means for traveling heavy loads.

With the introduction of the new Enerpac ML40 Mini-Lift Hydraulic Gantry and its built-in synchronization and safety features, operators can be confident in the performance of the ML40 for nearly any 40-ton lifting job, Enerpac said.

Nearly any 40-ton job can be done with the new ML40 Mini-Lift Gantry. As standard, the ML40 Mini-Lift Gantry includes stroke and travel synchronization with alarm functions to alert the operator should something become out of set tolerances. The ML40 Mini-Lift Gantry also comes standard with a wireless pendant control which keeps the operator away from the load when lifted. The wireless pendant includes a display that provides information such as load, stroke, alarm details and set-up screens.

When installing or removing machinery in tight spaces, compact gantry designs that require a minimal amount of clearance around the machine are a must. The ML40 fits through a standard personnel doorway and can be maneuvered into position manually. Time is saved by not having to move auxiliary equipment out of the way to get machinery moving equipment into place.

Specialized lifting machines are becoming more complex and far more difficult to handle and repair. But Enerpac gantries continue to advance in design to make moving and lifting easy and simple. The ML40 Mini-Lift Gantry is a complete, self-contained system with everything on-board including the pump, controls and drive system. Additional components such as skid tracks, header beams, lifting anchors and other accessories are available. The ML40 is simple to set up with a single wireless pendant control and runs off standard single phase 115 or 230 VAC power.

Shuttlelift

The SB series gantry crane lineup is ideally suited to today’s marketplace, in which components are getting longer, tandem picks are becoming more common and plant managers are looking for a more cost-effective way to do business, the company said. With just a single traversing beam and single hook, they act as an overhead bridge crane without the restrictions of the track, allowing product to be easily transported in a plant or yard without extra handling equipment.

The Shuttlelift SB series lineup of gantry cranes range from 15 tons to 150 tons capacity and greater.

The Shuttlelift SB series lineup of gantry cranes range from 15 tons to 150 tons capacity and greater.

The Shuttlelift SB series lineup of gantry cranes range from 15 to 150 tons capacity and greater. Each SB model is engineered as a unique lifting solution that solve material handling challenges and can work in tandem with another SB or Double Beam (DB) style gantries.

With Shuttlelift’s rubber-tired gantry cranes, loads are suspended directly beneath the frame so operators do not need to interpret complex stability charts. Users can also utilize every square foot of their yard and facility with one machine.

With options such as he patented All-Wheel Electronic Steering, a Shuttlelift mobile gantry crane can provide operations with maximum flexibility, maneuverability and precision handling in the most confined spaces. In addition, ownership of a Shuttlelift allows users to take full control of their schedule and make lifts when it’s most efficient for company and their crew, instead of scheduling and waiting for a rented crane to complete a project, the company said.

Mi-Jack

Trumbull Corporation recently purchased the widest Rubber Tired Gantry (RTG) crane Mi-Jack has ever manufactured for their dam expansion project at the Charleroi Dam south of Pittsburgh, PA.

Trumbull Corporation purchased the widest Rubber Tired Gantry (RTG) crane Mi-Jack has ever made for their dam expansion project at the Charleroi Dam south of Pittsburgh, PA.

Trumbull Corporation purchased the widest Rubber Tired Gantry (RTG) crane Mi-Jack has ever made for their dam expansion project at the Charleroi Dam south of Pittsburgh, PA.

The crane is a custom Travelift MJ70HD featuring a 110-foot inside clear width (ICW). Trumbull uses this crane to lay concrete and steel to fill the dam, and it hoists the steel rebar and concrete structures down towards 70 feet. As the dam is expanded, the Travelift MJ70HD will drive down the dam to refill with concrete. Due to this RTG crane’s impressive parameters, it is equipped with GPS steering, an option that maps out the crane’s driving path for consistent and accurate movement along the dam, the company explained.

There is also hoist and traverse synchronization on this crane, which allows for the operator to pick up product at a level pick every time, when the feature is turned on. Delivered in 2021, careful planning was necessary to ship this 110-foot ICW MJ70HD due to the length of the top beams. Special cranes were brought in on barges for erection.Mi-Jack Travelifts are American-made and customized for unique applications. There’s no tipping factor, no counterweight concerns, no outriggers and no-load charts. Users can simply pick and carry based on each Travelift’s rated capacity.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.