ER strand jacks lift 1.7-million-pound box

22 May 2023

Engineered Rigging was tasked with helping to build the largest aircraft hangar under construction in the United States. The 275,000 square foot hangar, part of the new United Parcel Service (UPS) Northwest Aircraft Maintenance Complex in Louisville, KY, will house two Boeing 747-8F aircraft, the largest in its fleet. A key component of the new hangar is a 380-foot-long box truss weighing 1.7 million pounds, positioned by Engineering Rigging’s strand jacks.

The impressive lift took 10 hours to complete, in 16-inch increments.

The impressive lift took 10 hours to complete, in 16-inch increments.

The box truss is part of the door side of the hangar, and it needed to be raised 80 feet. Its length (longer than a football field) and massive weight required careful planning. Engineered Rigging, which provided equipment rental and onsite support, joined forces with Hensel Phelps, general contractor; Midwest Steel, steel erector; and Ruby and Associates, lift engineer.

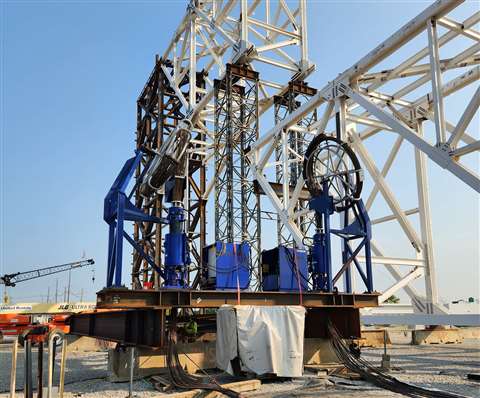

Engineered Rigging provided four 300-ton HSL30006 strand jacks, four SLPP15E hydraulic power units and a unique above jack strand managing recoiler system. After helping to load the strand, a single company operator, on the ground and positioned safely outside the lift zone, used computer controls to execute the 80-foot lift.

“Once we lifted the truss, our stand jack system mechanically supported the load overnight to allow the truss to cool,” said Mike Beres, director of operations for Engineered Rigging. “Because the strand jack system supported the load in place, workers could safely wait until temperature conditions were optimal to bolt the box truss into place. This process took several days to complete. “Our strand jacks provided the ability to safety wait.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.