Production starts on 3,000 tonne crane for BMS

30 June 2022

Claus Toft, BMS Heavy Cranes global director, offshore, and Tomas Zamarski, Huisman Czech Republic lead project manager, mark the start of production

Claus Toft, BMS Heavy Cranes global director, offshore, and Tomas Zamarski, Huisman Czech Republic lead project manager, mark the start of production

Dutch crane and heavy engineering specialist Huisman has started work to produce a 3,000 tonne capacity crane for Denmark’s BMS Heavy Cranes.

BMS signed up for the new giant on 6 January 2022 (see story). A primary application for the crane will be to help load wind turbine components onto foundations and offshore vessels.

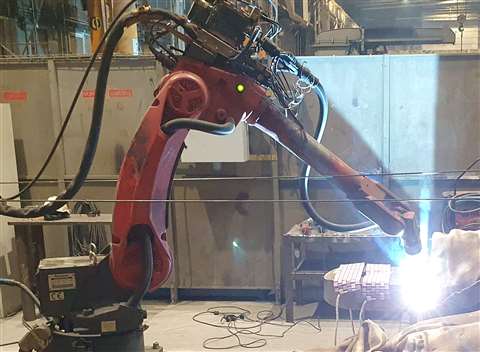

A ceremony to mark the start of production was held mid-June at Huisman’s production facility in the Czech Republic. The first two pieces, of S690 grade steel, were welded together using a robotic system.

Huisman also uses wire and arc additive manufacturing (WAAM), to make some components, including hook blocks. It is basically a 3D printer that works by building up layers of weld. Using this method mid-size to large components, with complicated shape, can be produced from high tensile steel. A major benefit of 3D printing, Huisman says, is it significantly reduces delivery time at a price to compete with forgings and castings. Quality is also consistently high, Huisman said.

Delivery of the crane is scheduled for the second half of 2023.

The fully electric crane will be able to lift 1,200 tonne components to a height of 225 metres. Loads up to 3,000 tonnes will be handled but at reduced height.

Robot welding and wire and arc additive manufacturing (WAAM) will be used to build the giant crane

Robot welding and wire and arc additive manufacturing (WAAM) will be used to build the giant crane

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.