Rounding up the latest below-the-hook products

24 October 2023

Below-the-hook products are continually evolving alongside rigging gear and equipment across the heavy lift spectrum. Often considered an extension of the hook, these devices are customizable for each lift, and bring efficiency and security to a project.

Load connection

The Caldwell Group has expanded its series of RUD ACP-Turnado lifting points, with Max and Supermax versions. A lifting point is a key below-the-hook product because it is the connection between the lifting gear and the load.

A practical feature of Max and Supermax versions is the deflector disc.

A practical feature of Max and Supermax versions is the deflector disc.

ACP stands for automatic center point. The RUD ACP-Turnado’s lift shackle turns in the load direction automatically when it is lifted, so it cannot remain in an incorrect position. Dangerous transverse loads and a sudden drop of the load are excluded, due to a unique spring mechanism.

With the relaunch, RUD has gone one step further in terms of working load limit (WLL), the company said. The smart ACP-Turnado lifting point is now available from M8 to M100 as well as ½ inch to 4-inches. This means that a suitable solution is now available for an even greater variety of applications, including extreme heavy-duty use.

A practical feature of Max and Supermax versions is the deflector disc. It is equipped with an angle marking and enables a quick, simple assessment of the current stop angle. As with smaller RUD ACP-Turnado lifting points, large versions have a universal bolt head with internal and external hexagon, which enables optimum handling. The bolt is captive, but still replaceable, which is useful in many applications. There is an adapted thread length for each dimension instead of a standard thread length across several sizes.

Dual purpose

Modulift’s Multi-Point is a strong, versatile lifting system designed to save rigging time and maximize use across multiple lifting applications. The system is designed and engineered for use as a semi-spreader or a lifting beam and is ideal for tandem lift operations and gives the user the power to lift across multiple points at varied spans.

The Modulift Multi-Point is also available with an optional swivel hook.

The Modulift Multi-Point is also available with an optional swivel hook.

Designed using the latest 3D Linear Analysis, and manufactured to BSEN 13155, the Multi-Point is engineered with multiple connection points on the top and bottom to provide flexibility for the beam to adapt to any situation – whether lifting a boat, reel, tank, turbine or anything else in between, the company said.

Featuring an adaptable and versatile modular design, the Multi-Point is ultra-portable and can be reused for hundreds of lifts. With easily detachable components, the beam lifts at spans from 3 to 12 meters, with a lifting capacity from 12 metric tons right up to 600 metric tons. Featuring an optional 360-degree swivel hook and extended support stands, the Multi-Point is an option for tandem lifts with two cranes when there is only one lower lifting point required and rotation of the load is critical. The Multi-Point Beam can also be used as a semi-spreader to give a more balanced lift, or as a lifting beam when headroom is restricted.

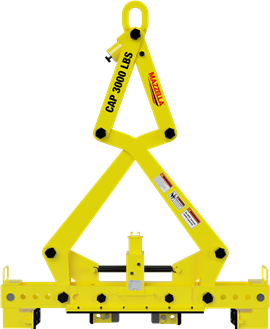

Mazzella manufactures vertical lifting tongs for coils.

Mazzella manufactures vertical lifting tongs for coils.

Width extension

Mazzella has engineered and manufactured a below-the-hook device for lifting coils in a vertical position. As the vertical lifting tong extends, the outer pads come together to press against the outer diameter of the coil, while the inner pads spread apart to press against the inner diameter of the coil.

The outer pads are adjustable in 5-1/2-inch increments with the largest distance in the open state being 51-1/4 inches compressing down to 44 inches in the closed state. The inner pads are adjustable in 4-inch increments with the largest distance in the open state being 14-1/4 inches expanding to 20-1/4 inches in the closed state.

Safety shackle

Dropped objects are a well-known safety hazard in the industry and have led to numerous accidents. Green Pin offers a unique solution to this problem: The Green Pin Catch Shackle BN prevents the accidental dropping of shackle bolts, nuts, cotter pins and even complete shackles, preventing injuries or deaths.

These shackles have an attachment point on each component to connect them to a lanyard. The Green Pin Catch Shackle BN has been developed in cooperation with DROPS, the non-profit organization that is focused exclusively on dropped objects prevention schemes. The Green Pin Catch Shackle BN is suitable for both one-leg and multi-leg systems and is available in a range with a working load limit from 2 tons up to 9.5 tons.

The Green Pin Catch Shackle is a below-the-hook device to prevent dropped objects on the jobsite.

The Green Pin Catch Shackle is a below-the-hook device to prevent dropped objects on the jobsite.

Locked and loaded

Peerless Industrial Group launched their IBC (Intermediate Bulk Container) Tote Lifter, ideal for lifting IBC Totes with an overhead crane. The IBC Tote Lifter is available to fit the standard 275- or 330-gallon container. Additional sizes are also available.

All IBC Tote Lifters are proof tested to 125 percent capacity in accordance to OSHA requirements.

All IBC Tote Lifters are proof tested to 125 percent capacity in accordance to OSHA requirements.

Operators are able to lower or traverse the lifter in place, straddling the IBC Tote. The dual steel load bars slide under the IBC Tote through the designated pocket areas. The lower clevis design (openings facing inward) allows for the load bars to easily connect to the lifter with only one operator required for placement. Lower bars lock in place with the sliding T-handle pins at the four corners of the clevises. Each lower bar has elongated slots instead of holes, to make it easier for the operator to drop the T-handle pins in place.

Fork to hoist

Lift-All’s new patent-pending GripHook design converts a forklift into a lightweight overhead lifting device in a matter of seconds. This is a must for contractors, manufacturing plants, power plants, distribution centers, rental houses and any other facility using fork trucks, the company said.

Lift-All’s new GripHook design converts a forklift into a lightweight overhead lifting device.

Lift-All’s new GripHook design converts a forklift into a lightweight overhead lifting device.

The self-gripping design allows the GripHook to tighten around the fork when a load is applied. The easy-to-attach GripHook does not require any tools to install. This economical solution is made from high-quality synthetic materials saving money without compromising lift capacity, according to Lift-All. Easy to install, lightweight and self-gripping, the GripHook turns a forklift into a hoist with options to lift up to 2-tons in a matter of seconds.

“The GripHook instantly turns any fork truck into a hoist, thus enabling increased production and better lifting efficiencies,” said Jason Dively, vice president of sales, Lift-All. “The innovative design ensures safety while providing a versatile range of lifting options in a number of different environments.”

Forged links

Skookum alloy steel Master Links and Master Link Subassemblies are drop forged up to 1 ½ inches and robotically welded from 1 ¾ inches and larger. Skookum forged links are quenched and tempered, and offer superior grain refinement and ductility, providing superior strength, the company said. All links are marked in accordance with ASME B30.26. Skookum’s proof test fixture design prevents localized loading per ASTM A952.

Skookum Master Links are Shell Offshore approved and made in the USA.

Skookum Master Links are Shell Offshore approved and made in the USA.

Sling strength

Taurus Lifting Slings are the latest below-the-hook innovation from Samson. At the core is a multi-loop strength-optimized High Modulus Polyethylene (HMPE) sling, protected by a high-visibility braided polyester chafe body featuring non-weight-bearing braided HMPE chafe eyes. Flexible and lightweight with high strength and excellent abrasion resistance, these general-purpose lifting slings are essential to any lifting job, the company said.

Taurus Lifting Slings conform to ASME B30.9 and are rated for use with comparable hardware, such as shackles of equivalent strength specification. Slings are available with vertical Working Load Limit (WLL) ranging from 30,000 to 400,000 pounds and are available in lengths from 10 to 50 feet (size dependent).

Taurus Lifting Slings are an off-the-shelf solution designed to reduce overall implementation time.

Taurus Lifting Slings are an off-the-shelf solution designed to reduce overall implementation time.

Each sling comes tagged with WLL for vertical, basket and choker configurations at a safety factor of 5.

Secure solution

Jergens has combined key features of its SP2000 and Shackle-Lok hoist rings for a new, productive and secure solution to die flipping. Two versions are offered – standard and Lift-Check – to ensure worker safety and required clearance. Die flipping is a standard process of rotating and inverting die plates for cleaning oils and metal chips as well as for routine maintenance.

The additional clearance helps customers in their die-flipping applications.

The additional clearance helps customers in their die-flipping applications.

“That is no small task given that these plates can be very large in size and weigh (up to) thousands of pounds,” said Chris Spada, Jergens LSG and SFG product manager. “First and foremost, when lifting anything of this nature is worker safety. To that end, Jergens manufactures its hoist rings to strict quality standards, proof tests each one to 200 percent of the load and then certifies them.”

Another matter of key importance is to maintain the structural integrity of the die plates. “One of the design drivers was to make sure users have (chain) clearance for things like die shoes and external plumbing that mount off the ends,” Spada continued. Ensuring zero contact is critical to maintaining the precision and functionality of the die. The side pull design has an offset neck and provides 360 degrees of swivel and 180 degrees of pivot to clear all die components.

Load stabilization

Users can remotely operate the VLN device from distances up to 600 feet away.

Users can remotely operate the VLN device from distances up to 600 feet away.

Vita Inclinata’s Vita Load Navigator (VLN) is a solution for lifting and moving loads with precision, designed to improve load stability, optimize operational efficiency and enhance safety. The VLN is offered in standard models, which differ in size and torque, to match sites’ unique lifting needs, as well as fully tailored builds and solutions. All models are semi-autonomous propulsion-driven devices that connect below the hook of the crane and are remotely controlled.

The VLN is capable of measuring more than 1,000 data points every second. The system detects load movement in real-time and utilizes high-powered fans to prevent issues like spinning, rotations and other problems that may cause injuries or damages at the site.

The Mod Bar can be used as a single beam.

The Mod Bar can be used as a single beam.

Operators can optimize load positioning and movement, significantly improving productivity on the jobsite. With the auto hold feature, they can keep loads in position in the toughest of conditions.

Multi-point lifts

Lone Star Rigging’s MULTIS Mod Bar was designed with flexibility and ease of adjustment in mind when making numerous multi-point lifts with varied center of gravities and un-uniform lift locations, depending on weight and lifting point requirements. The MULTIS Mod Bar can be used as a single beam with varied and multiple pick points or as a frame with widths up to 30 feet. The lengths range from 20 to 90 feet.

Adjustments for CG end-to-end are made by shifting the lifting bells above each pick point so that the load is under the hook for side-to-side offset CG. Adjustment is made by selection of the shackle position on the upper Mod Bars which keeps the CG under the hook. Number of pick points can be as few as four or as many as needed based on lifting lug or column locations. The MULTIS Mod Bar uses only the needed number of lift points, and the frame is positioned over the center of gravity. It saves man hours in rigging adjustment from one lift to another, prevents the need for custom sling lengths, minimizes head room, rigging weight and reduces assets on site.

Talking tools

Don’t forget to inspect the hoist per ASME B30.21 recommendations as well as the manufacturer’s recommendations.

Don’t forget to inspect the hoist per ASME B30.21 recommendations as well as the manufacturer’s recommendations.

The team at All Material Handling and Peter Cooke, president of National Rigging and Crane, have come up with a few tips to help decide on the right tool to use.

First, how much tension will you be putting on the hoist? Second, how are you anchoring the hoist to the load? Third, how much clearance do you have? The three main factors here are:

■ Length – the distance the lifting hook can travel between its fully lowered and fully raised positions.

■ Reach – being equal to the difference in height between the hang point (top hook, pad eye, or pin) and the saddle of the hook in its lowest position.

■ Headroom – the distance from the hang point and the fully raised hook saddle. For hoists with a top hook, the headroom dimension is the distance from the hang point of the top hook and the saddle of the fully raised lower hook.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.