What are the latest crane operator aids on the market?

19 April 2022

A collection of load moment indicator, rated capacity limiter and related technologies.

Weight, wind speed, power line proximity and a host of other variables must be measured to assure safe crane operations. The best way to assess all of these is through technology, mainly in the realm of Load Moment Indicators (LMIs) and Rated Capacity Limiters (RCLs).

This technology has come a long way in the past decade, with these systems now considered critical operator aids. Many of these systems feature remote updating and position programming.

Cranesmart Systems

Cranesmart’s newest LMI4 Display Panel was designed with industry top of mind, according to Justin Evans, Cranesmart Systems sales manager.

Cranesmart’s LMI4 display panel

Cranesmart’s LMI4 display panel

Utilizing the LMI4 Display Panel, Cranesmart gives the crane industry the functionality and performance they covet, while still offering the simplicity behind the system-operation that its customers have come to expect from Cranesmart, Evans said.

New functionality includes spare transducer compatibility between systems, giving customers the in-field flexibility to manage their systems. Cranesmart Systems also feature remote firmware updates and increased data logging capacity. Programming or load chart modifications and seamless data logging is now available via the USB port in the back of the LMI4 Display Panel. These systems also offer absolute position programming for the correct selection of load charts, relative to the crane’s operating location. For cranes working in marine or offshore applications where onboard/offboard or static/dynamic load charts are applicable, Cranesmart’s Absolute Position feature will automatically select the correct load chart, in real-time.

There is also powerline proximity protection utilizing Cranesmart’s newest Powerline Proximity Transducer.

“We’re keeping operators on the right side of power lines, regardless of the equipment-type or jobsite entailments,” Evans said. Another important functionality is winch payin/payout. Operators can now get real-time information on their block height during winch movement.

“We believe strongly in harnessing customer feedback towards our pursuit of cutting edge technology, made simple for every end-user,” said Evans. “With over 40,000 systems in operation, our customers around the world have come to know the Cranesmart Systems mission is to provide the highest quality safety equipment and operator aids, paired with the best after-the-sale service in the industry. We offer crane safety made simple. It’s one panel, one system, one phone call.”

For an animation of the Crane Smart Systems functionality visit https://youtu.be/lKGximvnBcg.

Greer LMI

A TWG company, Greer produces one of the most well-known LMI monitoring and alert system in the crane industry. Designed as one of the easiest interfaces on the market, the Greer system has intuitive menus, and its screens reduce operator training time and increase crane productivity.

Greer TS 7

Greer TS 7

Greer’s newest innovation monitors crane operation continuously and provides vital data that crane operators need to maximize efficiency. Greer LMIs are easily calibrated to a crane’s load chart using technology that ensures fast installation. The Greer LMI is engineered for predictable performances, regardless of weather. Greer’s LMI products include the Insight, Element II, TS 7, Last Layer Indicator, Gear Drive with Area Definition, Reeling Drum, Anti-Two Block Switch and Light Bar.

As well, Greer produces windspeed indicators. The company recently introduced the Greer WSI, touted as the only windspeed indicator on the market with no moving parts.

Greer Wind Speed Indicator

Greer Wind Speed Indicator

The WSI includes a 2.8-inch color screen, custom wind speed alarms with red, yellow and green zones, horn output for audible alarm capability, data retrieval via USB stick and maximum wind speed gust indicator. It can be used stand alone or integrated in a Greer LMI system. The range is 0 to 85 miles per hour.

RaycoWylie

Serving the global market since 1933, RaycoWylie’s i4500 RCL series utilizes a high-resolution color display in 4.3-inch, 7-inch and 10-inch screen formats. The system was developed with two main criteria in mind: simple installation and serviceability, according to Manon Huard, OEM sales manager for RaycoWylie.

RaycoWylie’s i4507

RaycoWylie’s i4507

“The user-intuitive functions, accuracy and easy self-diagnostics are what attracts customers to adopt this system as their standard,” she said. “Based on the CAN bus J1939 protocol, it can monitor all of the necessary lifting parameters, work area and forbidden zones and also can integrate crane engine and hydraulics data.”

The CAN bus network permits huge amounts of flexibility allowing the addition of sensors at any time throughout the life of the equipment. The i4500 all-in-one concept with camera reduces the number of displays in the cab permitting the operator to keep focus on the load, for safety and productivity.

WIKA

The qSCALE Ix is a standard LMI solution that meets the requirements for both OEM and aftermarket applications. The system provides the operator with a graphic display of the crane’s boom length, boom angle, load radius and current load – both actual and allowable.

WIKA’s qSCALE lx

WIKA’s qSCALE lx

The 4.3-inch or 7-inch color graphic display includes an integrated bar graph to provide the operator with the crane’s current utilization. The system offers the flexibility of using both wireless and hardwired sensors and also features a simplified calibration procedure using a menu-driven process, which reduces calibration time.

For OEMs looking to fully customize their LMI, the qSCALE offers the flexibility to modify and add system options beyond a standard LMI solution. This includes machine-specific graphics and adding additional sensors based on specific application requirements. This system also offers the option of custom communication with non-LMI functions such as air-conditioning, engine diagnostics, outrigger monitoring and the like.

WIKA’s qSCALE lx

WIKA’s qSCALE lx

The qSCALE maestro LMI is an aftermarket upgrade solution for the DS150G, DS350G/GW and existing maestro systems that are currently in the field. The qSCALE maestro offers a flexible design that converts existing software, eliminating the need for re-calibration. The system features a 4.3-inch color display that displays actual and allowable load, boom length, boom angle and load radius. The qSCALE maestro features an integrated light-bar and event recorder and offers the option of an external light-tower. With an IP 66/67 rating, the console can be mounted either inside or outside of the cab.

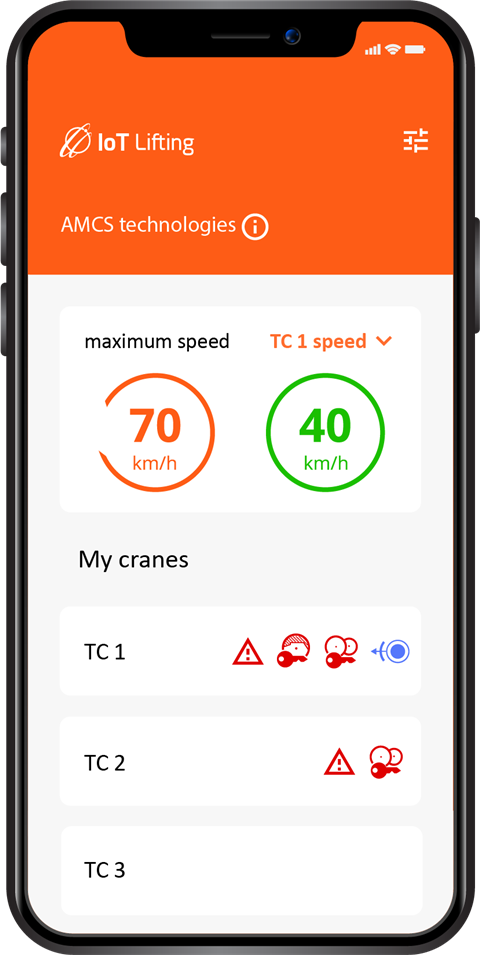

AMCS technologies

The LMI remains an indispensable tool for crane operators, according to AMCS technologies.

AMCS technologies IoT Lifting App

AMCS technologies IoT Lifting App

“Operator aids evolve in functionality and design as technology continues to become more sophisticated,” said Radoine Bouajaj, president of AMCS technologies. “They give the operator a dramatically improved perspective on all of his machine’s data for real-time use and a better confidence on driving aid device. Our anti-collision and zoning device for tower cranes has an LMI function.”

Safety on the jobsite is always a priority.

“The display’s graphical user interface provides every information crane operators need to drive their machines, and it is an aid to the operator,” Bouajaj said. “The sensors are placed on the machine and retrieve real-time information from the crane. This information is sent directly to our system. When the device is installed on the crane, the crane parameters (jib length, height, etc.) are all programmed.”

When the crane operator performs an action – lifts a load, slews, etc. – the display function on the screen placed in his cabin indicates the load, slewing position, trolley position, hook height, travelling position on the track for travelling cranes, wind speed and luffing angle.

AMCS technologies DCS 61-S

AMCS technologies DCS 61-S

“We believe that the trend is towards the digital transition and consequently to the enlargement of the fields of competences in order to offer comfort options to the customers,” he said. “Today, not only the crane operator receives the cranes information in real time, thanks to the IoT Lifting Mobile App and Web platform on our last anticollision system the DCS 61-S.”

With a SIM card, the DCS 61-S systems continuously collects information of the various sensors placed on the cranes. As such it is possible to store, send and receive all collected information on the IoT Lifting App and Web and even to create user specific statistics, Bouajaj said.

“It is possible to remotely monitor a jobsite’s productivity with precision, knowing the daily activity of your cranes, managing your fleet of AMCS technologies products as well as carrying out remote diagnostics.”

The Dynamic Load Monitoring DLM 60t Running Line Monitor measures the tension on a rope passing through its three wheels. Typically used in cable laying and winch operations to measure and record line tension the robust design has become an industry standard.

Dynamic Load Monitoring Running Line Monitor

Dynamic Load Monitoring Running Line Monitor

The monitor can be supplied as a separate item for integration with customers’ existing PLC’s or with a DLM digital display/HMI touch screen display.

Features include a fully sealed, robust design suitable for harsh environments, integral speed and distance and measurement as well as tension.

The DLM 60t is easy to rig without the need to remove sheaves from axles and features lifting and securing points, optional mounting fixtures.

Applications include winch load monitoring, towing and salvage, PLGR, cable laying and crane load monitoring.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.