What are the latest developments in wire rope research?

10 November 2022

Wire and fiber rope research is intense. D.Ann Shiffler reports.

Over the past decade, a handful of crane OEMs have partnered with wire and synthetic rope manufacturers to research the idea of replacing heavy wire rope with lighter fiber rope. The idea is to reduce weight without conceding strength.

Python Commercial Director of Wire Rope Sven Balbiani said that most crane OEMs are satisfied with the wire rope products currently available.

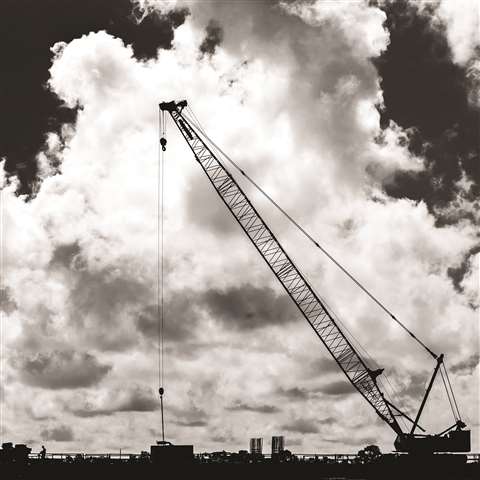

Several crane OEMs have researched the idea of replacing wire rope with fiber rope. It’s a complicated endeavor with many variables to consider. Photo © Robert Dimmitt Photography

Several crane OEMs have researched the idea of replacing wire rope with fiber rope. It’s a complicated endeavor with many variables to consider. Photo © Robert Dimmitt Photography

“We do not see too much interest in this topic amongst our OEMs,” Balbiani said. “There is one overhead crane manufacturer who has put up a whole product line that can be equipped with fiber rope or steel wire rope.”

The majority still opt for steel wire rope.

What are the benefits of synthetic ropes?

WireCo has also worked with OEMs to explore opportunities for synthetic ropes to serve as alternative solutions to steel wire rope.

“The primary purpose in doing so is to reduce weight without compromising strength, increasingly a concern as lifts become higher, heavier and more complex,” said, Andreas Schmeiss, vice president of WireCo. “Synthetic ropes also tend to be easier to handle and install, reducing fatigue and the possibility of injury for those who conduct installations, inspections and change-outs. And, without any need for lubrication, fiber ropes offer environmental benefit.”

But for all its advantages, fiber does pose some important challenges.

“In the industrial environment, in which ropes frequently encounter sharp edges and abrasive surfaces, steel is generally impervious, while fibers are susceptible to fraying,” he said. “Fibers are also sensitive to ultraviolet radiation and excessive heat. High temperatures can cause a condition known as ‘creep,’ in which a rope becomes pliable and stretches to a point beyond its original form.”

Ultraviolet radiation can degrade rope filaments, requiring that special coatings be applied to prevent failure, he said.

“Retirement criteria are also more difficult to determine with synthetic ropes, where the nondestructive testing methods used to judge the condition of a steel rope are not suitable,” he said. “Synthetic ropes tend to be more expensive than steel wire ropes. For the same application, the cost of fiber can exceed that of steel by up to three or four times.”

With both steel and synthetic products, WireCo has solutions for a given end use, regardless of the material, Schmeiss said.

“Fiber rope helps reduce the required rope diameter tremendously,” Balbiani said. “In some cases, steel is the clear winner. In other cases, fiber. Advanced coatings might one day tip the balance in favor of synthetics, but, for now, it would be difficult to imagine that fiber rope would fully displace steel any time soon.”

Fiber lends itself well to static applications, particularly in the maritime environment.

“These include applications in which ropes are not continually wound and unwound over drums,” said Schmeiss. “WireCo, through Lankhorst Ropes, has a long history of employing synthetic ropes to moor ships, offshore energy platforms and, more recently, floating wind turbines. These ropes are transported and installed at sea, making synthetics’ reduced weight, high strength, ease-of-handling and corrosion resistance the preferred choice over steel.”

WireCo recently introduced the Union Gladiator series of boom pendants, a fiber-based rope for mining shovels.

“Unlike the steel used in conventional pendants, Gladiator’s synthetic Aramid fibers act like a shock absorber during digging operations, reducing fatigue-related stresses for both the shovel equipment and those who operate it,” said Schmeiss. “This, in turn, could extend the service lives of shovels and draglines by up to three to four times over the lives typically experienced when using traditional steel technologies.”

Fiber also has potential for wider use in dynamic applications. Synthetic slings and are well accepted in the lifting sector.

Breaking load and weight

Mobile cranes, however, present a special challenge, as ropes must strike an optimal balance between breaking load and weight.

Balbiani cited three companies offering a fiber rope on their cranes/hoists. A crane using fiber rope is an exception, not the rule, he said.

Schmeiss said both the limited axle loads of road-approved vehicular cranes and weight limitations for crawler cranes require that ropes provide a steadily increasing breaking load at a constant diameter. To meet these requirements, synthetic alternatives must employ special fibers with tensile strengths similar to those of steel, he said.

Lankhorst Ropes’ LankoLift S does this, Schmeiss said. The yellow rope consists of 12 braided outer strands made of high-tech Dyneema and provides a breaking strength equal to that of steel rope of the same thickness. LankoLift’s core is designed to resist transverse pressures, and laboratory tests involving reversed bending cycles have yielded promising results. The rope also features a special fiber coating that reduces interior friction and increases ultraviolet resistance.

“LankoLift crane test participants have been consistently impressed with the product’s low weight, flexibility and ease of handling during installation and hook block changes,” Schmeiss said. “The rope has proven suitable for higher payloads, especially those involving higher lifting heights and longer jib lengths. The low maintenance requirements offer further advantage, since synthetic ropes of this type are corrosion-proof and require no further lubrication.”

And then there’s the idea of merging wire and fiber rope – a hybrid rope. Python is researching this concept as well.

“The bottom line is that fiber rope bears a cost disadvantage that only becomes balanced when the operations are very expensive, for example deep shaft mining, and the relatively low reduction in total weight accumulates over a long length in favor of payload, [like] increasing a skip’s capacity from 30 to 40 tons in a 3,000 meter deep shaft,” said Balbiani. “Due to economic turbulences, we have currently iced these projects and will go ahead when supply chain problems have resolved.”

WireCo offers the Casar TurboLite M, a hybrid mining rope with a plastic-coated, high-strength fiber core, surrounded by steel-wire strands. This construction provides a high strength-to-weight ratio, as well as resistance to abrasion and bending fatigue. It was designed for use in underground mining, where shafts have become progressively deeper and weight the limiting factor in hoisting capacity, Schmeiss said.

“As with other applications that favor synthetics, reduced weight is a clear benefit,” Schmeiss said. “The same is true of the added durability and reduced creep provided by hybrid ropes. In terms of downside and factors that would limit wider use, cost is likely the most significant.”

A lot of research has been conducted on hybrid ropes. The main objective has been to substitute the independent wire rope core of a conventional steel wire rope with a high performance synthetic rope that also has supportive load-bearing features.

Liebherr Cranes is using fiber ropes on some of its tower cranes.

Liebherr Cranes is using fiber ropes on some of its tower cranes.

High performance synthetic ropes are used on utility truck cranes for transmission wire and transformer applications. These ropes are being used on tower cranes, RTs and even overhead cranes. The elevator industry is also researching the use of hybrid ropes.

Hybrid ropes are designed with a blend of steel wires and high performance fibers that combine the characteristics of both products.

We are always looking for ways to decrease weight on a crane without compromising the mechanical properties for lifting. The mobile crane market demands ropes with a high break strength and non-rotating characteristics for long lifts and increased weights. Also, we must realize that end fittings – such as swage or spelter buttons, sockets and wedge sockets – have the ability to make the termination of the hybrid rope to complete the installation.

Inspection criteria of standard wire ropes have been in place for a long time. Since the introduction of high performance synthetic ropes, inspection criteria is also documented. High performance synthetic ropes have been predominantly used in the utility truck applications with much shorter lifts and very few, if any, parts of line through the block. With that said, inspection criteria for high performance synthetic ropes is very important, requiring proper education for daily inspection and third-party inspection. Inspection of these ropes has generated a lot of discussion. A critical subject is damage. If a steel wire rope jumps a sheave, the outer steel wires can withstand the abuse. But with high performance synthetic rope, very small diameter fibers can be cut between the sheave and block.

Research will undoubtedly continue. A hybrid robe gives more answers when it comes to inspection and damage assessment. And there maybe be some comfort knowing that a hybrid rope is protected by steel wire with the internal lighter fibers fulfilling the strength, flexibility and torque balance characteristics.

THE AUTHOR

Tony Fastuca, Vice President of ASC Industries Python America, has been in the wire rope industry since 1979. Based in Germany, Python provides engineered ropes for customers around the world.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.